Power Generation

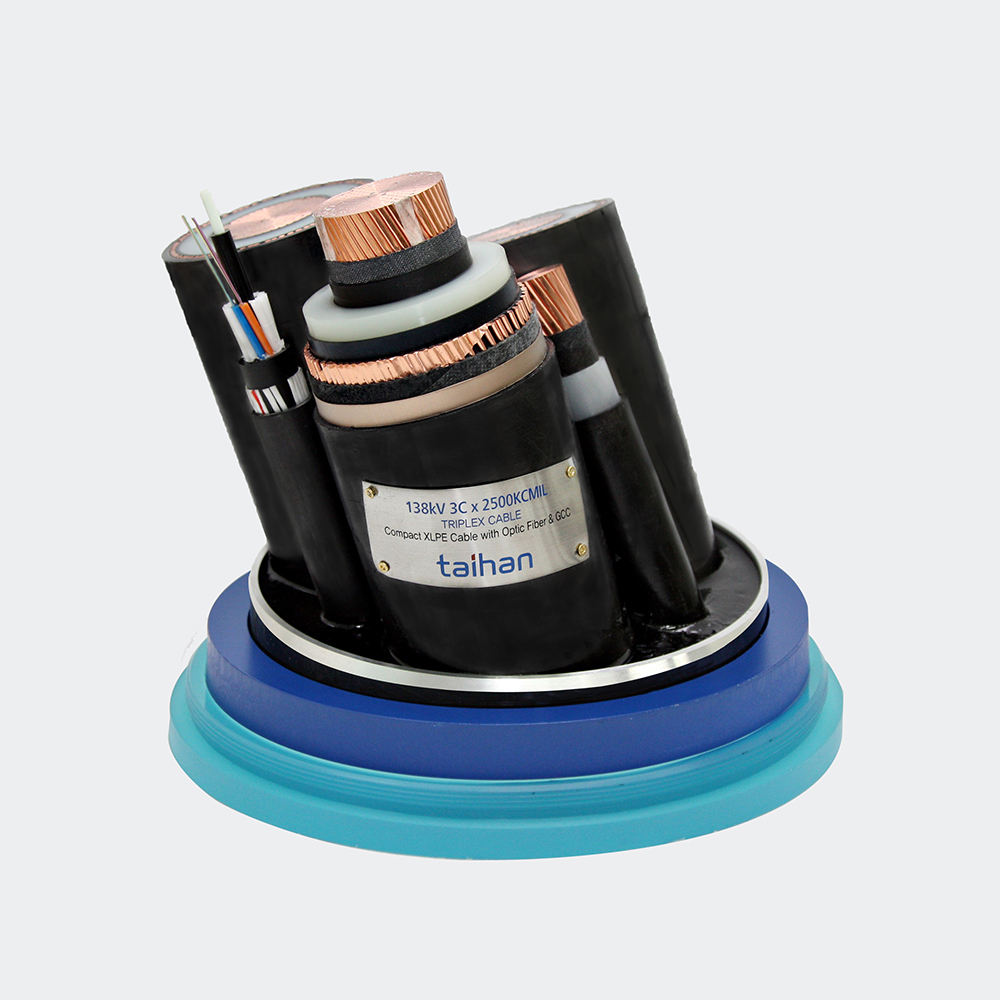

Extra-High Voltage OF Cables

공유하기Oil-filled (OF) paper insulation cables have a history of over 100 years, and use insulating paper impregnated with low-viscosity insulating oil as an insulator. By applying a pressure higher than atmospheric pressure, the gap in the insulator is completely removed and as a result, the cables have very good electrical properties.

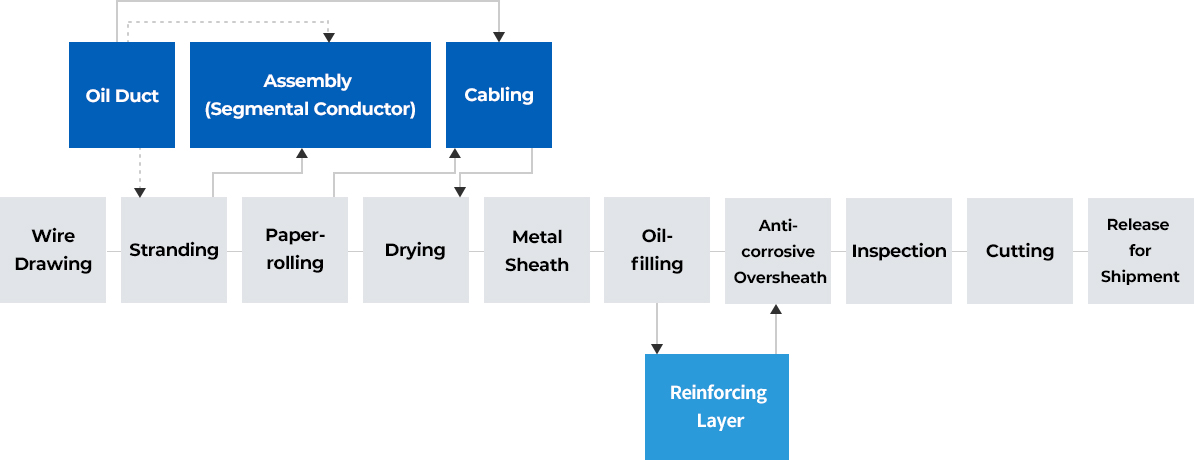

- Manufacturing

Process -

EHV OF cables are manufactured through the processes of wire drawing, stranding, paper-rolling and drying.

For the manufacturing, paper-rolling, drying, and oil-filling constitute are core processes

- Paper-rolling tension : Prevents undesireable moisture, dust, and other foreign substances from entering the cable insulation

- Drying process : Removes moisture from the paper-rolled core

- Oil-filling process : Injects the reserved insulating oil into the metal sheath to fill the core

- Types and Uses

-

66~400kV OF cable: This cable is used for building underground power grids in cities and large industrial complexes.

- Features

-

- Excellent electrical stability

- Small cable outer diameter

- Control the expansion and contraction of insulation oil depending on temperature change into the pressure oil tank

- Early detection of cable faults

Related Contents

Related solutions

Product Quick Search

Find the product you need quickly and easily

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)